Facts About Inventory Management Uncovered

Wiki Article

See This Report about Inventory Management

Table of ContentsThe Basic Principles Of Inventory Management 7 Easy Facts About Inventory Management ExplainedA Biased View of Inventory ManagementEverything about Inventory Management

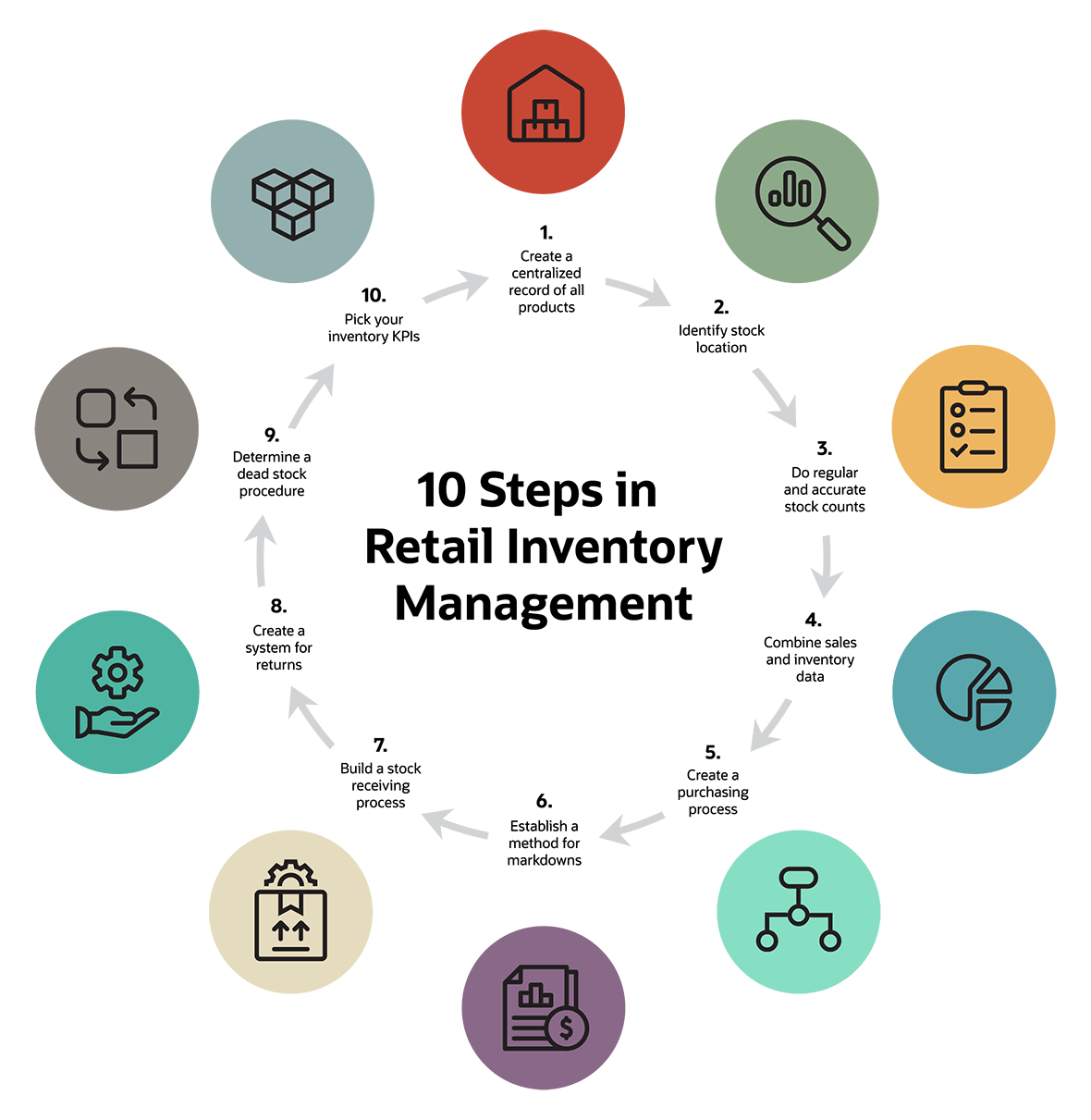

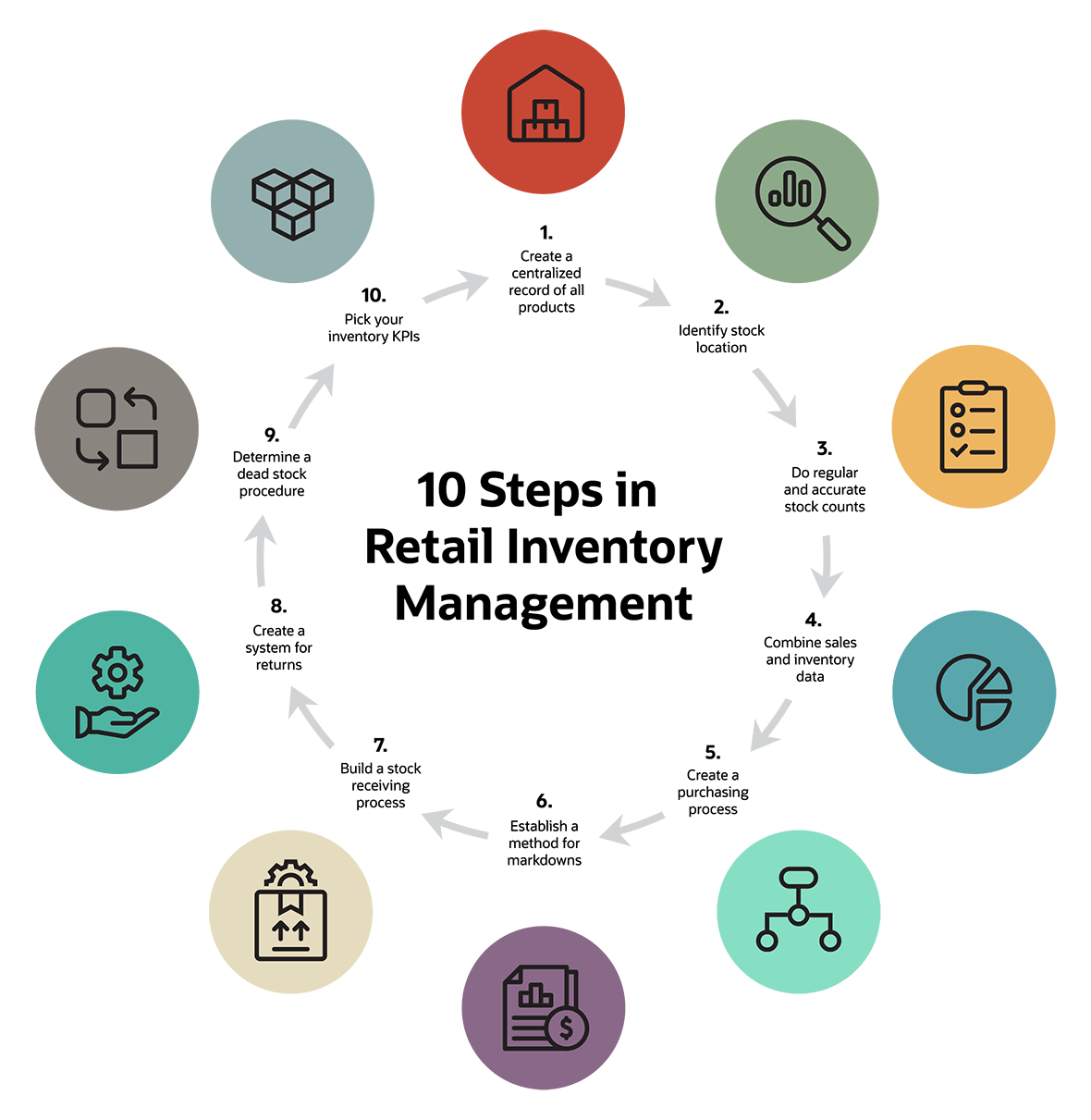

There are two major approaches of tracking inventory: periodic and also perpetual. The major difference between these is just how frequently information is upgraded. No matter of how often you track supply, you may desire to use one of the adhering to inventory management strategies: ABC Evaluation, ABC (Always Better Control) Analysis is stock administration that separates different items into 3 groups based upon rates as well as is divided into teams A, B, or C.EOQ Version, Economic Order Quantity is a method made use of for planning and also purchasing an order quantity. It includes making a choice relating to the quantity of inventory that must be positioned in stock at any offered time.

FSN Approach, This method of inventory control describes the procedure of monitoring all the items of stock that are not utilized frequently or are not required at all times. They are after that classified into three different classifications: fast-moving inventory, slow-moving inventory, as well as non-moving supply. JIT Approach, In the nick of time supply control is a procedure made use of by producers to regulate their supply levels.

The Inventory Management PDFs

VED Evaluation, VED is a method made use of by companies to manage their stock. The high level of supply that is needed for manufacturing usually warrants the reduced inventory for those components.Wrike's product launch automation assists accelerate item launches with a streamlined approach.

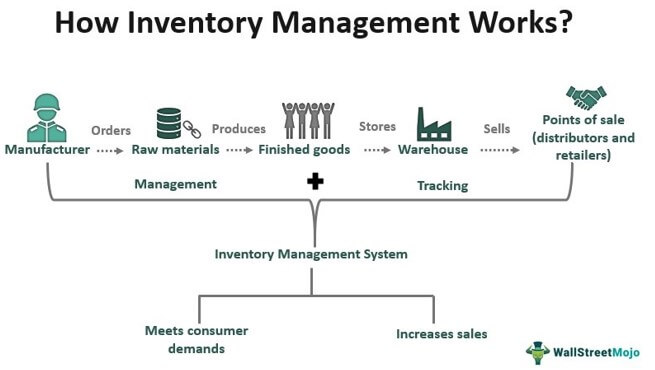

Supply administration attempts to effectively enhance supplies to avoid both gluts as well as lacks. 4 major inventory monitoring methods include just-in-time monitoring (JIT), products need planning (MRP), economic order amount (EOQ), and days sales of supply (DSI). There are pros and cons to each of the methods, reviewed below. A company's inventory is among its most valuable possessions.

A shortage of supply when as well as where it's needed can be very destructive (Inventory Management). At the Visit This Link exact same time, supply can be taken a liability (otherwise in an audit sense). A huge inventory carries the danger of spoilage, theft, damage, or changes sought after. Inventory must be guaranteed, as well as if it is not offered in time it might need to be taken care of at clearance pricesor just damaged.

Recognizing when to restock supply, what quantities to buy or generate, what rate to payas well as when to market as well as at what pricecan quickly ended up being complicated decisions. Local business will typically monitor stock by hand and also identify the reorder factors as well as amounts making use of spreadsheet (Excel) solutions. Larger organizations will certainly utilize specialized enterprise source planning (ERP) software application.

Inventory Management Fundamentals Explained

Proper stock administration approaches vary depending on the sector. An oil depot is able to keep big quantities of supply for prolonged durations of time, allowing it to wait for demand to get. While storing oil is costly and riskya fire in the U.K. in 2005 caused countless pounds in damages as well as finesthere is no risk that the supply will certainly spoil or go out of style.For firms with complex supply chains and manufacturing procedures, balancing the dangers of supply gluts as well as scarcities is particularly challenging. To achieve these balances, companies have actually developed numerous methods for inventory administration, consisting of Go Here just-in-time (JIT) and also products requirement planning (MRP). Some companies, such as economic solutions companies, do not have physical stock as well as so should count on solution procedure administration.

Supply has to be physically counted or measured before it can be placed on a balance sheet. Finished items are completed items easily available for sale to about his a company's consumers. Depending on the kind of organization or item being assessed, a company will make use of various inventory management techniques.

Report this wiki page